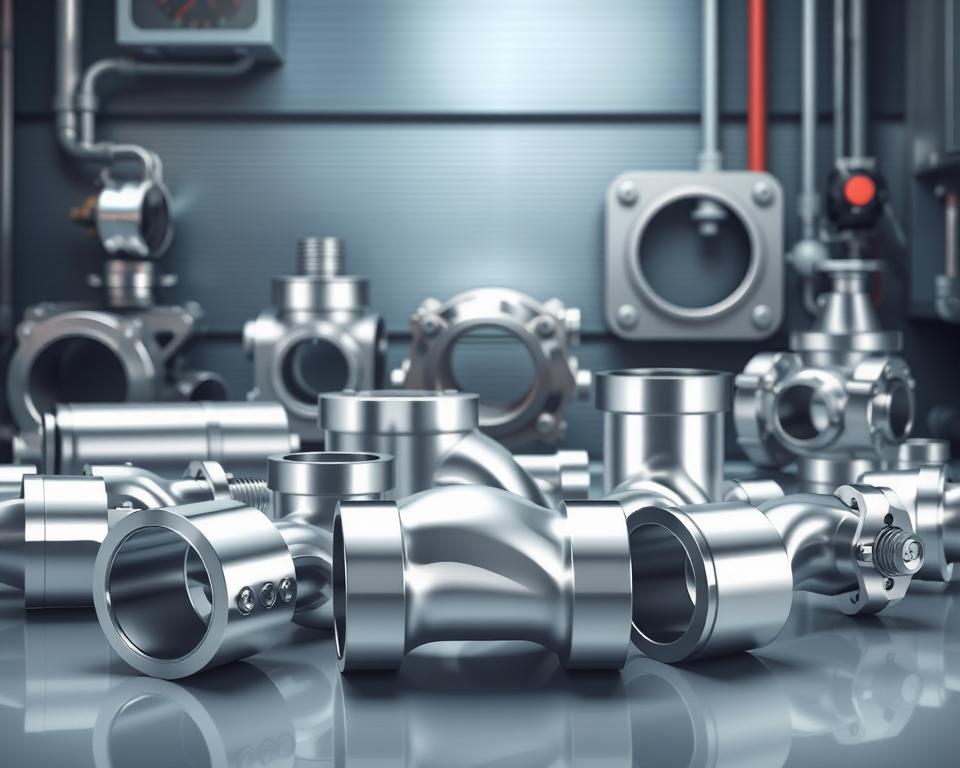

Premium Tri-Clamp-Style Sanitary Fittings for Ultra-Clean Operations

In settings where cleanliness saves lives, even microscopic gaps matter. Hence, companies like Installation Parts Supply specialize in exactingly crafted solutions aimed at reducing danger. Their hygienic connection systems unite robustness with tool-less construction, positioning them as a top choice for facilities that insist on flawless results.

These parts do more than stopping drips – they’re designed to exceed the tough needs of food-grade production, beverage production, and pharmaceutical manufacturing. Manufactured using chemical-resistant stainless, they survive repeated washdowns while keeping rigidity. The conceptual approach echoes industry leaders like Alfa Laval, placing first Tri clamps fittings smooth surfaces and fast release.

How do these connectors stand out? Think one-handed installation and equipment-free care. Technicians appreciate the user-friendly layout during hectic production schedules, while supervisors favor uniformity across pipelines. Every piece receives tight verification to satisfy FDA and 3-A Sanitary Standards.

Primary Conclusions

- Adopted by industry pros for leak-proof performance in mission-critical zones

- Made from heavy-duty stainless steel for robust longevity

- Streamlines adherence to food safety and pharmaceutical regulations

- Decreases idle periods through hand-tightened buildup and washdown

- Underwritten by QA systems on par with global benchmarks

Component Synopsis and Major Gains

Dependable joints are the backbone of sterile workflows. Installation Parts Supply develops components that merge fine-tuned tolerances with practical functionality. Their systems grant airtight performance while reducing maintenance hassle—critical for fields where quick production meets sanitation.

Top-Grade Quality and Hygiene Standards

Every component faces intensive trials to reach international criteria. The materials withstand chemical attack, even after continual wash-downs. Tight gaskets block pathogen buildup, a feature valued by dairy processors and pharmaceutical manufacturers alike.

These parts emulate the standards of leaders like Alfa Laval, providing smooth surfaces and uniform dimensions. Configurable designs fit into current lines, reducing retrofit costs. Technicians record 30% speedier setups compared to traditional threaded systems.

Supplier-Specific Advantages

Bespoke machining distinguishes this company. Demand a tricky angle or custom sheen? Their team teams up with buyers to engineer tailored solutions. Immediate dispatch and 24/7 technical support reduce downtime.

The advantages reach beyond lifespan. Snap-apart removal shrinks pauses during sanitation audits. Liquid processing sites using these connectors experience fewer production stoppages and balanced streams. It’s not just about hitting the rules—it’s about outperforming standards.

Engineering Specs & Construction Details

High-accuracy design marries adaptability in current manufacturing networks. Installation Parts Supply builds components that pair accurate metrics with versatile designs. Their strategy provides seamless integration into installed systems while upholding stringent sterility standards.

Bespoke Metals & Finishes

No two projects are identical. That’s why alloy selections include 304 and 316L, preferred for strength and corrosion resistance. Surface treatments like electro-finishing produce mirror-like smoothness, decreasing pathogen grip by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes employ optical scanners to ensure uniform wall thickness. Precision limits (±0.005″) avoid frail sections in pressure-heavy systems. During quality checks, components receive X-ray scans and pressure tests to identify microscopic flaws.

Tailoring surpasses looks. Clients demand particular elbows, flange sizes, or dedicated coatings for chemical resistance. These made-to-order choices help industries satisfy emerging guidelines without re-engineering full setups.

Implementation and Use-Cases for Tri-Clamp Sanitary Links

Current quick-turn operations call for units that mount rapidly yet run dependably. These connection systems prove ideal in environments where efficiency partners with purity. Their design removes tool complexity, empowering teams to retain focus on throughput rather than assembly headaches.

Quick-Install Workflow

Twin flange lips and a centered gasket generate error-proof locks in seconds. Workers position the parts, insert the squeeze band, and seal by hand – no wrenches required. This method lowers setup slips while ensuring uniform force across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Versatile Bridges Across Equipment

Connecting clean pipes to vessels, these interfaces bridge diverse components effortlessly. The uniform design mates to various diameters, permitting swift transitions during product changeovers. Dairy plants commonly employ them for toggling between cleaning cycles and production runs with zero hassle.

Maintenance teams favor how components break apart for thorough sanitation. Smooth surfaces prevent residue buildup, while the threadless build removes crevice dangers. Weekly cleanings require 50% less effort compared to older connection methods.

Industry Applications and Compliance Standards

Whether in micro-breweries or biologics factories, modern facilities depend on parts that fit varying demands while meeting exacting rules. Installation Parts Supply delivers solutions relied on across key markets where product purity is essential. Their designs connect throughput to legislation, engineering networks that succeed under stress.

F&B plus Pharma Fields

Inside culinary process sites, rapid-swap fittings make alternating between flavors and sanitizing simple. Breweries rely on custom tees to manage complex flow paths with zero blend danger. Pharmaceutical manufacturers rely on tight gaskets to defend reactive substances during sterile transfers.

These fittings come in multiple sizes to match piping layouts, from benchtop rigs to massive brewhouses. Dairy processors value how standardized parts minimize stoppages during equipment upgrades. Even minor tweaks in production processes are handled through modular designs.

Compliance with ASME/ISO/3-A

Every component matches and outperforms benchmarks set by global organizations. ASME-certified materials endure thermal stress in pasteurization systems, while ISO-compliant finishes prevent bacterial buildup. The 3-A symbol guarantees suitability for direct contact with consumables.

Tri-clover fittings illustrate the dedication. Their uniform dimensions provide drip-free service across automated lines. Third-party audits validate supply chain from raw materials to finished goods, providing inspectors certainty.

By matching these guidelines, facilities smooth approval workflows and sail through reviews. It’s not just about sidestepping fees—it’s about building consumer trust through obvious compliance.

Summary & Suggested Actions

Picking hardware that blends productivity with code guides plant achievements. Installation Parts Supply supplies systems fusing robustness with sterile engineering, guaranteeing leak-free performance across food, pharma, and beverage environments. Their products hit rigorous standards while smoothing regular duties through easy install.

With variants in steels and textures, solutions adapt to unique process requirements. Whether transporting heated slurries or regular CIP runs, material choices and surface treatments enhance life cycle. Professionals praise the wide selection of connection types matched to given flow speeds and psi loads.

Getting parts is easy, with specialist help on hand to align line requirements. Rapid dispatch and prompt customer care slash outage risk during upgrades or replacements. Standard sanitation becomes effortless thanks to quick-release joints and clean bores that deter deposits.

Looking to improve operational trust? Get in touch with Installation Parts Supply to review personalized setups – from tri-clover to tri-clover designs – reinforced by premium QC. Their team makes sure you satisfy today’s rules while positioning you for upcoming needs.